doTERRA produces pure essential oils thanks to CPTG quality testing

CPTG quality testing

The purity of an oil is its most important characteristic. If an oil is not pure, you risk exposing yourself to bacteria, heavy metals or adulterated material. This can cause irritation, adverse effects or even illness. Because there is no recognized standard of purity for essential oils, doTERRA has created its own testing process:CPTG Certified Pure Therapeutic Grade®.

The CPTG process ensuresthat there are no fillers, synthetics, or dangerous contaminants in the essential oil that would diminish its effectiveness. doTERRA goes one step further and also subjects all products and packaging to a series of tests to ensure that they have a long shelf life and can be stored. This process ensures the potency, purity and consistent quality of each batch. The correct harvesting and distillation methods are also essential for the purity of an oil. Poor production practices and the development of synthetic versions of essential oils suggest that scientific analytical methods are required to identify pure oil.

Before the CPTG process begins

The precise analysis of the ingredients of an essential oil is one of the biggest and most complex challenges in quality assurance. If you want to produce oil of the highest quality, you first have to know which plant of the many different types offers the greatest therapeutic benefit. The plant material is carefully selected with the expertise of botanists, chemists and aromatherapists for its natural concentration of active aromatic compounds.

In order for an optimally pure and effective oil to be extracted, the plants must be cared for, carefully harvested and transported in the best possible environment. The cultivators and farmers of the global doTERRA network are experts in the field of plant cultivation for the extraction of essential oils.

The CPTG process

The CPTG test procedure begins immediately after distillation. Each oil is immediately examined for its chemical composition. A second test is carried out at our production facility to ensure that the oil received is the same oil that has already been tested on site. In a 3-phase process, the oil is then examined a third time after it has been bottled for the end user. Each of these tests ensures that the essential oil is free of impurities and has not been altered.

To obtain the CPTG® seal, the following tests are carried out:

- Organoleptic tests

- Microbial tests

- Gas chromatography

- Mass spectrometry

- Fourier transform infrared spectroscopy (FTIR)

- Chirality testing

- Isotopic analysis

- Heavy metal testing

Gas chromatography used to be sufficient to determine the individual components of an essential oil. However, as more sophisticated processes for producing synthetic essential oils were developed, new testing methods were needed. Over time, other methods such as mass spectrometry, chirality testing, FTIR scanning, carbon isotope analysis and other methods have been developed to further determine the components of an essential oil.

Organoleptic tests

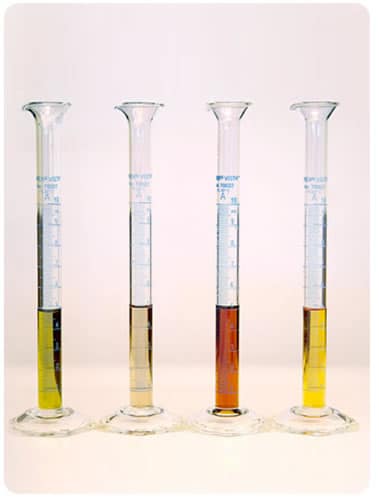

Organoleptic testing involves the use of the human senses: appearance, smell, taste and touch are evaluated. For an experienced distiller, the senses are the first way to get clues about the quality of the essential oil. If it smells unusual, doesn’t have a consistent consistency, or is an unusual color, the distiller immediately knows that something is wrong with the product. This is usually the first test procedure that an oil has to go through.

Microbial tests

Microbial testing takes place to examine a batch of essential oil for dangerous microorganisms found in nature such as fungi, bacteria, viruses and mold. The procedure involves placing a sample on sterile growth medium in a sealed container. The sample is then incubated for a certain period of time and checked for microbial growth. This test is carried out first when the oil arrives at the production center and a second time after the products have been filled to ensure that the product has not been contaminated during filling.

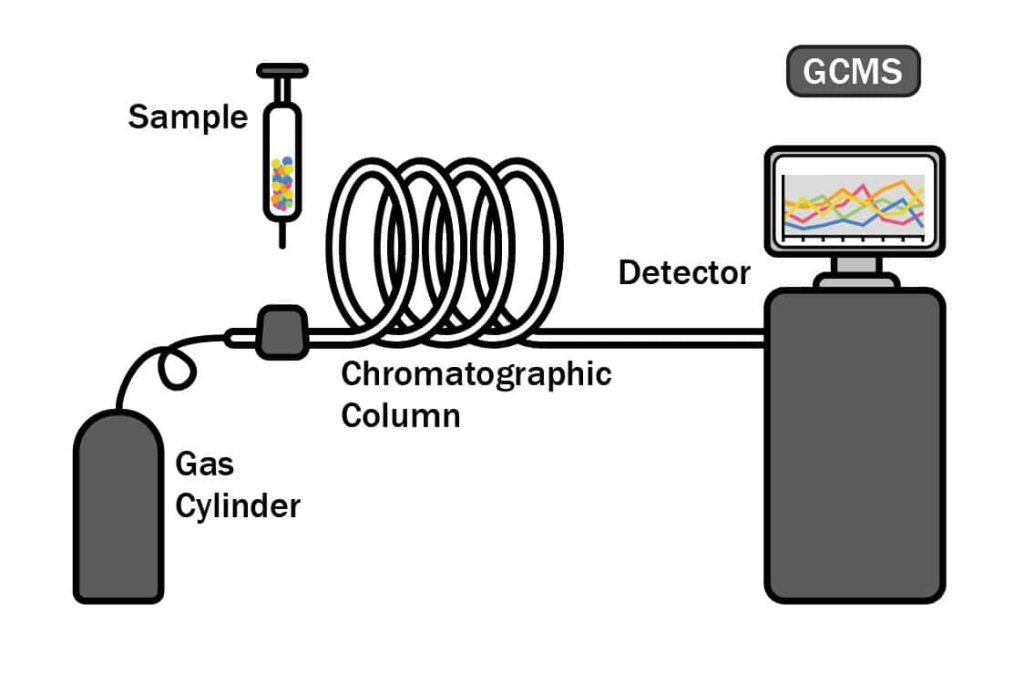

Gas chromatography and mass spectrometry analysis (GC/MS)

Gas chromatography involves vaporizing essential oil through a long tube to separate the oil into its individual components. Each component rises through the tube at different rates based on its molecular mass and chemical properties and is measured as it exits the tube. This testing method allows quality control analysts to determine which compounds are present in a sample.

Mass spectrometry is used in conjunction with gas chromatography to further determine the composition of an essential oil. In mass spectrometry, the components that were initially separated by GC are ionized and passed through a series of magnetic fields. Based on the molecular mass and formal charge, the amount of each component can be determined. In this way, further information about the effectiveness of the essential oil can be collected.

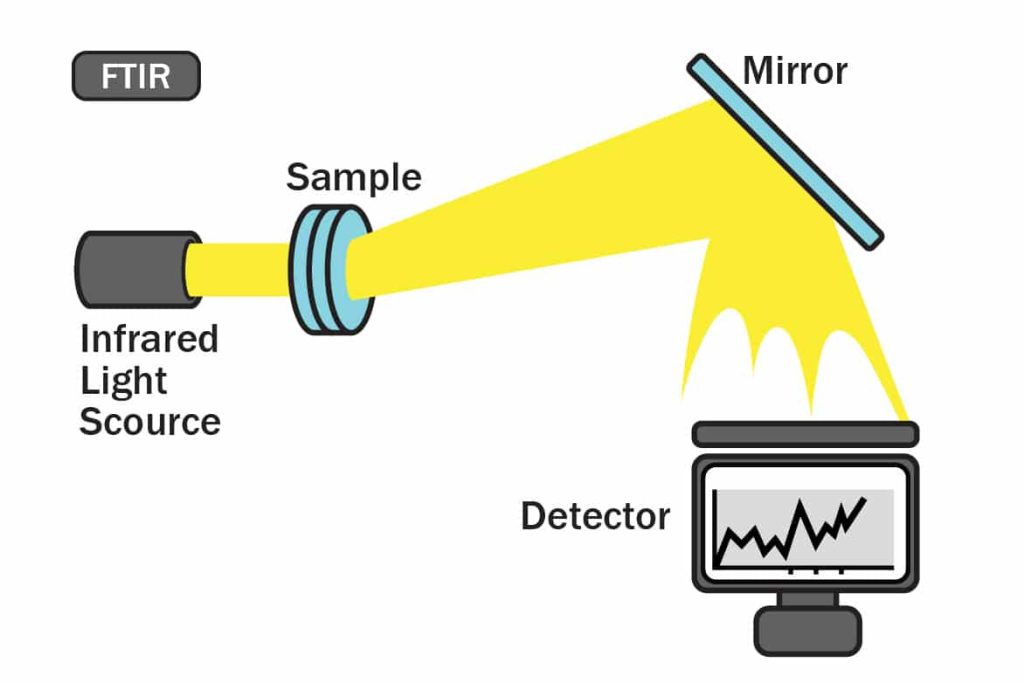

Fourier transform infrared spectroscopy

Fourier Transform Infrared Spectroscopy (FTIR) is performed to ensure the potency and consistent quality of each batch. The testing method determines the structural components of the essential oil compounds. An FTIR scan involves sending infrared light at different frequencies through an oil sample and measuring the amount of light absorbed. The quality of the sample is determined by comparing the results of the FTIR with entries from a database of absorbance results from high quality samples.

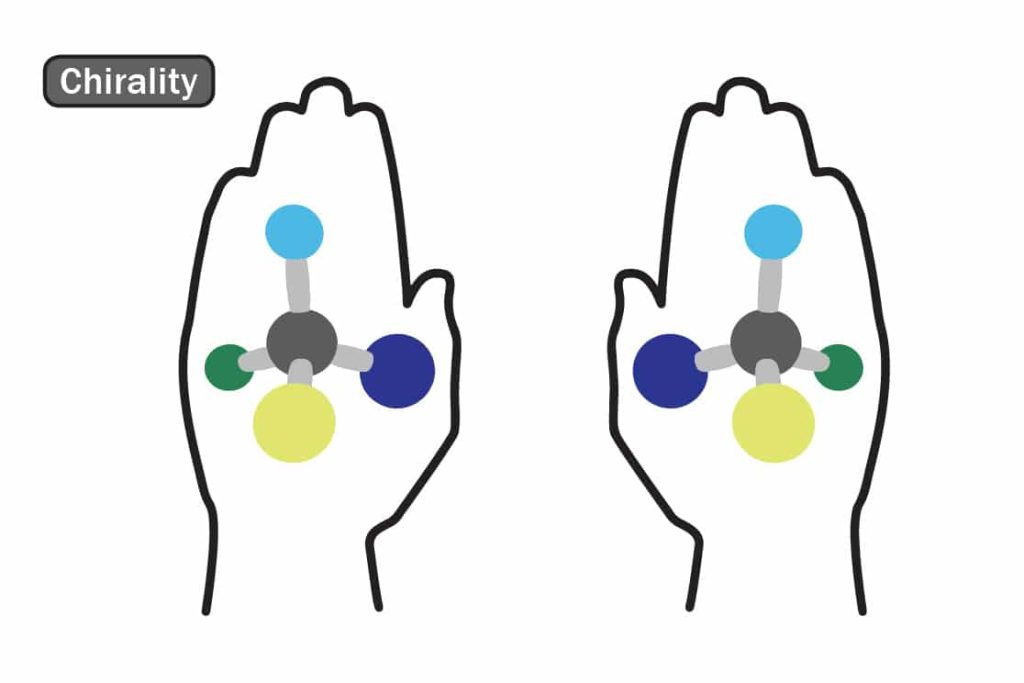

Chirality testing

The term chirality, derived from the Greek word for “hand,” is used to describe the spatial arrangement of atoms in a molecule. Just like two hands, chiral molecules exist in two shapes that can be distinguished like the left hand from the right hand. They mirror each other like a left and a right hand. If you place them on top of each other, they are still different, no matter how you turn them. When it comes to molecules, each “hand” has different chemical properties that influence their physiological interactions in the body. In nature, one hand always predominates. However, in the laboratory, the ratio of the left and right molecules is always 50/50 due to the structural similarities. The ratio between left and right molecules can be determined using a special gas chromatography. Although not performed on every batch, this test is intended to ensure that no synthetic elements are present in the oil.

Isotopic analysis

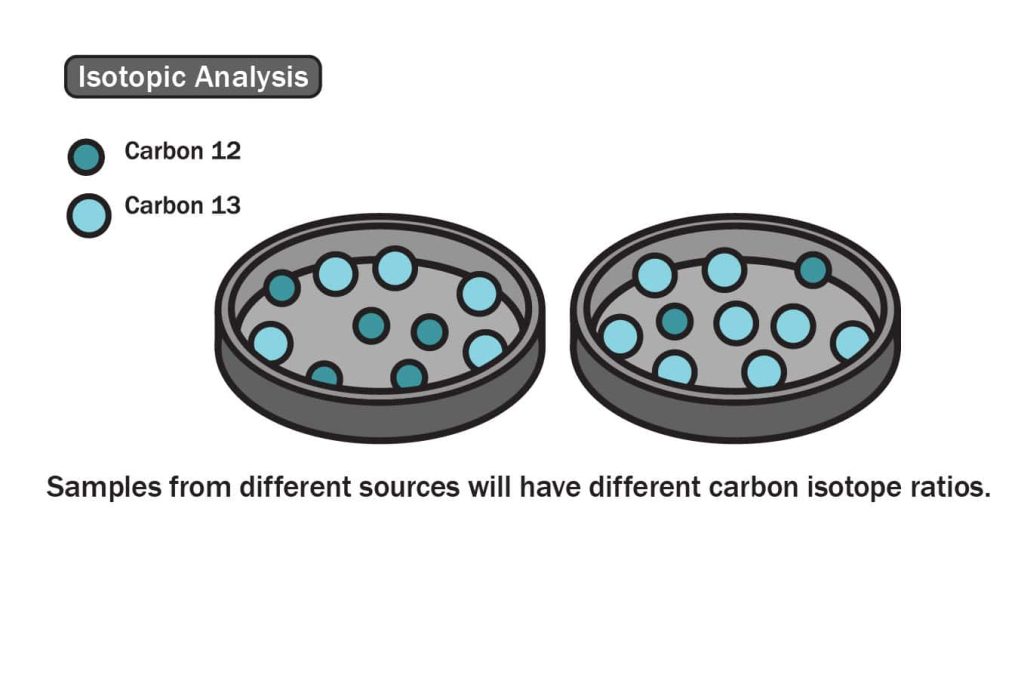

Matter is made up of tiny chemical building blocks called elements. Although there are dozens of elements, each is different because of the protons it contains. Sometimes an element can have different properties if the number of neutrons it contains varies. One then speaks of isotopes. The element carbon exists in two stable isotopes 12C (6 protons and 6 neutrons) and 13C (6 protons and 7 neutrons). Since essential oils are organic compounds, they are mostly composed of carbon atoms and have a certain ratio of 12C and 13C isotopes. However, the ratio varies depending on the location.

A special form of mass spectrometry makes it possible to determine which isotopes are present in an essential oil and in what quantities. For essential oils from the same location, the ratio of isotopes should be the same for each component. If a particular component has a different isotopic profile, this tells the quality control analyst that the oil has been altered.

Heavy metal testing

Heavy metal tests show how high the proportion of heavy metals is in the essential oil. If essential oil is distilled correctly, it should not contain any heavy metals. ICP-MS (inductively coupled plasma mass spectrometry) testing uses a high-energy medium called inductively coupled plasma to ionize the sample. The sample runs through mass spectrometry, which divides the examined material into its basic components so that it can be determined which elements are contained in which proportions.